In the simplest terms, temperature and humidity sensors are electronic devices engineered to measure and report the ambient temperature and the amount of water vapor present in the air. These two parameters are fundamental to understanding and controlling a vast array of physical and biological processes. While a single device can measure both, they are often distinct components working in tandem. The accurate quantification of these environmental variables is a cornerstone of modern automation and control systems. They are the silent sentinels, providing the crucial data needed to maintain optimal conditions.

The Science Behind Their Operation

The operational principles of these sensors are a fascinating blend of physics and material science. Temperature sensors, or thermistors, often rely on the principle that the electrical resistance of a material changes predictably with temperature. As the temperature rises, the resistance of a thermistor can either increase (Positive Temperature Coefficient, PTC) or decrease (Negative Temperature Coefficient, NTC). This predictable change allows for the precise calculation of the temperature. Humidity sensors, on the other hand, typically measure the relative humidity (RH), which is the ratio of water vapor in the air to the maximum amount of water vapor that could be in the air at a given temperature. A common method is the capacitive sensor, which uses a hygroscopic polymer that absorbs or releases water molecules, causing a change in its dielectric constant and, consequently, its capacitance. This change in capacitance is then converted into a humidity reading.

Key Types and Technologies

Analog vs. Digital Sensors

The distinction between analog and digital sensors lies in how they transmit their data. Analog sensors output a continuous voltage signal that is proportional to the measured parameter. This output requires an analog-to-digital converter (ADC) to be processed by a microcontroller. They are often less expensive and can be suitable for simple applications. Conversely, digital sensors have an integrated ADC and communicate their readings as a digital bit stream, often using protocols like I²C or SPI. This eliminates the need for an external ADC and reduces noise interference, leading to greater accuracy and ease of use in complex systems. Their direct communication simplifies integration with microprocessors and other digital components.

Capacitive, Resistive, and Other Sensing Principles

The market is replete with diverse technologies for sensing humidity. The capacitive sensor, as mentioned, is a dominant technology. Its reliability and compact size make it ubiquitous. The resistive humidity sensor, another common type, uses a change in the electrical resistance of a material as it absorbs water vapor. Typically, this material is a ceramic or a polymer with ions that become more mobile when exposed to moisture, thereby decreasing the resistance. There are also thermal conductivity sensors, which measure the difference in thermal conductivity between dry air and humid air. Each technology has its own strengths and weaknesses concerning accuracy, response time, and cost, making the selection process a matter of matching the sensor’s characteristics to the specific requirements of the application.

Applications Across Industries

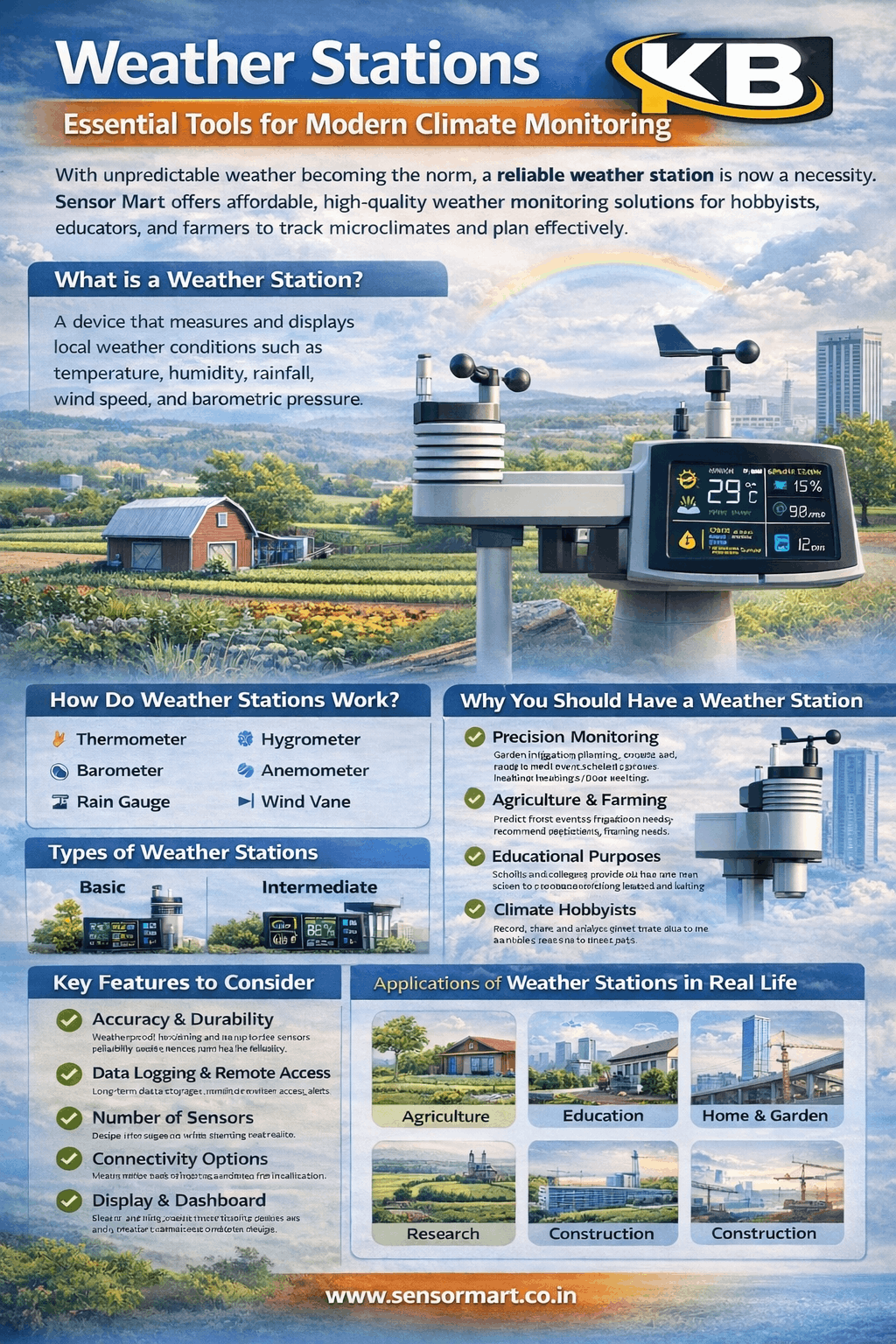

HVAC and Environmental Control

Temperature and humidity sensors are the linchpin of modern HVAC (Heating, Ventilation, and Air Conditioning) systems. They provide the real-time data necessary for thermostats and smart controllers to regulate indoor climate effectively. By continuously monitoring the air, these sensors enable a system to maintain a comfortable and healthy environment, preventing issues like mold growth or static electricity buildup. In commercial buildings, they are critical for energy management, ensuring that heating and cooling are only activated when needed, leading to significant energy savings and a reduced carbon footprint.

Industrial and Manufacturing Processes

In industrial and manufacturing settings, the control of temperature and humidity is not merely about comfort but about product integrity and process efficiency. Industries such as electronics manufacturing, pharmaceuticals, and textile production are highly sensitive to environmental conditions. For instance, the fabrication of semiconductors requires ultra-precise control of humidity to prevent electrostatic discharge, which can destroy sensitive components. In food processing, these sensors ensure that products are stored at the correct temperature and humidity to prevent spoilage and maintain quality. They are integral to quality assurance and process control.

Agriculture and Food Storage

In the realm of agriculture, these sensors are revolutionizing farming practices. They are deployed in greenhouses and vertical farms to create a perfectly optimized microclimate for plant growth. By providing data on soil moisture and ambient conditions, they facilitate intelligent irrigation and nutrient delivery systems, leading to higher yields and reduced resource consumption. In food storage and logistics, temperature and humidity sensors are essential for monitoring conditions in refrigerated trucks and cold storage facilities, ensuring that perishable goods arrive fresh and safe for consumption. This monitoring is critical for compliance with food safety regulations and for minimizing waste.

Choosing the Right Sensor

Crucial Specifications to Consider

Selecting the correct sensor is a nuanced process. Several specifications are paramount. Accuracy and precision are often conflated but are distinct; accuracy refers to how close a measurement is to the true value, while precision refers to the repeatability of a measurement. Measurement range is another key factor, as the sensor must be able to operate within the expected range of its environment. Response time, or the speed at which the sensor reacts to a change, is critical for dynamic processes. The power consumption of the sensor is also a significant consideration, especially for battery-powered or remote applications. Finally, the interface type (analog, digital) and the physical form factor (probe, surface mount) must be compatible with the system in which the sensor will be integrated.

Calibration and Maintenance

Even the most sophisticated sensors require periodic calibration and maintenance to ensure their continued accuracy. Over time, sensor readings can drift due to aging components or exposure to contaminants. Calibration involves comparing the sensor’s output to a known standard and making adjustments as necessary. Many sensors come with a recommended recalibration schedule. Proper maintenance, such as cleaning the sensor head of dust or other particulates, is also crucial for preserving performance. For critical applications, redundant sensors and self-diagnostic features are often employed to guarantee continuous, reliable data.

The Future of Environmental Sensing

Integration with IoT and Smart Systems

The future of temperature and humidity sensing is inextricably linked with the Internet of Things (IoT). As devices become increasingly interconnected, sensors will not merely collect data, they will be part of an intelligent network. IoT-enabled sensors can transmit their readings to the cloud for real-time analysis, enabling predictive maintenance, smart automation, and unprecedented levels of control. This integration will lead to more energy-efficient buildings, more responsive supply chains, and more personalized environmental control in homes and workplaces. The paradigm is shifting from simple measurement to holistic, data-driven environmental management.

Miniaturization and Advanced Materials

Technological advancements are driving the relentless miniaturization of sensors. We can now embed these devices into virtually any object, from clothing to medical implants. Concurrently, the development of advanced materials is creating sensors that are more durable, more accurate, and can operate in more extreme environments. Microelectromechanical systems (MEMS) technology, for example, is enabling the fabrication of incredibly small and precise sensors. The use of novel polymers and nanomaterials is also opening new frontiers, allowing for sensors that can detect minute changes with extraordinary sensitivity, paving the way for innovations in healthcare, sustainable living, and beyond.

Leave a Reply