I. Introduction: The Unsung Pillar of Industrial Integrity

In the vast ecosystem of commercial and infrastructural operations, the humble tripod stand frequently operates out of sight, yet its role is fundamentally non-negotiable. It is the unheralded foundation upon which precision is built and safety is maintained. Without this stable anchor, critical measurements would falter, and safety protocols would be rendered null. The best industrial tripod stands are defined not by aesthetic appeal, but by an unwavering, quantifiable commitment to structural exigence.

I.A. Differentiating Industrial from Consumer-Grade Supports

It is paramount to establish a clear delineation between a standard photographic tripod and its rugged industrial counterpart. Consumer models prioritize portability and optical stabilization for finite-duration tasks; industrial stands, conversely, are engineered for persistent, high-load scenarios in unforgiving environments. They are the scaffolding for vital instruments, demanding materials like high-grade aluminum alloy and stainless steel that resist dynamic loads and systemic degradation. Their design mandate centers on providing unimpeachable perpendicularity for instruments weighing significantly more than a camera, ensuring absolute structural constancy over weeks or months of continuous deployment.

II. The Taxonomy of Industrial Deployment

The application landscape for these supports is diverse, necessitating specialized design profiles. A unit optimized for securing a surveillance camera in a factory is structurally distinct from one intended to anchor a high-resolution terrestrial laser scanner.

II.A. Precision Metrology and Geomatics

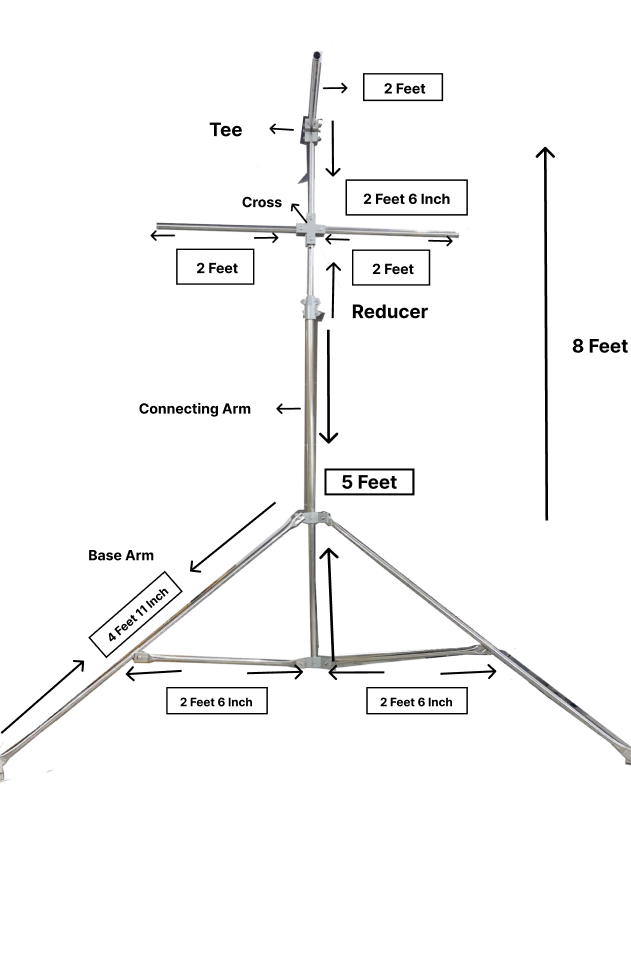

The fields of geomatics and industrial metrology rely entirely on the absolute rigidity of the instrument base. Surveyors and engineers using total stations or GPS receivers demand tripods that exhibit near-zero horizontal drift. Even microscopic angular deflection, when extrapolated across vast distances, can lead to catastrophic calculation errors in structural integrity or civil engineering projects. For these applications, stands are engineered with robust, locking mechanisms and wide footprints (up to 120 centimeters in base diameter) to maximize the anti-overturn prophylaxis, ensuring the instrument’s center point remains invariant throughout the survey period.

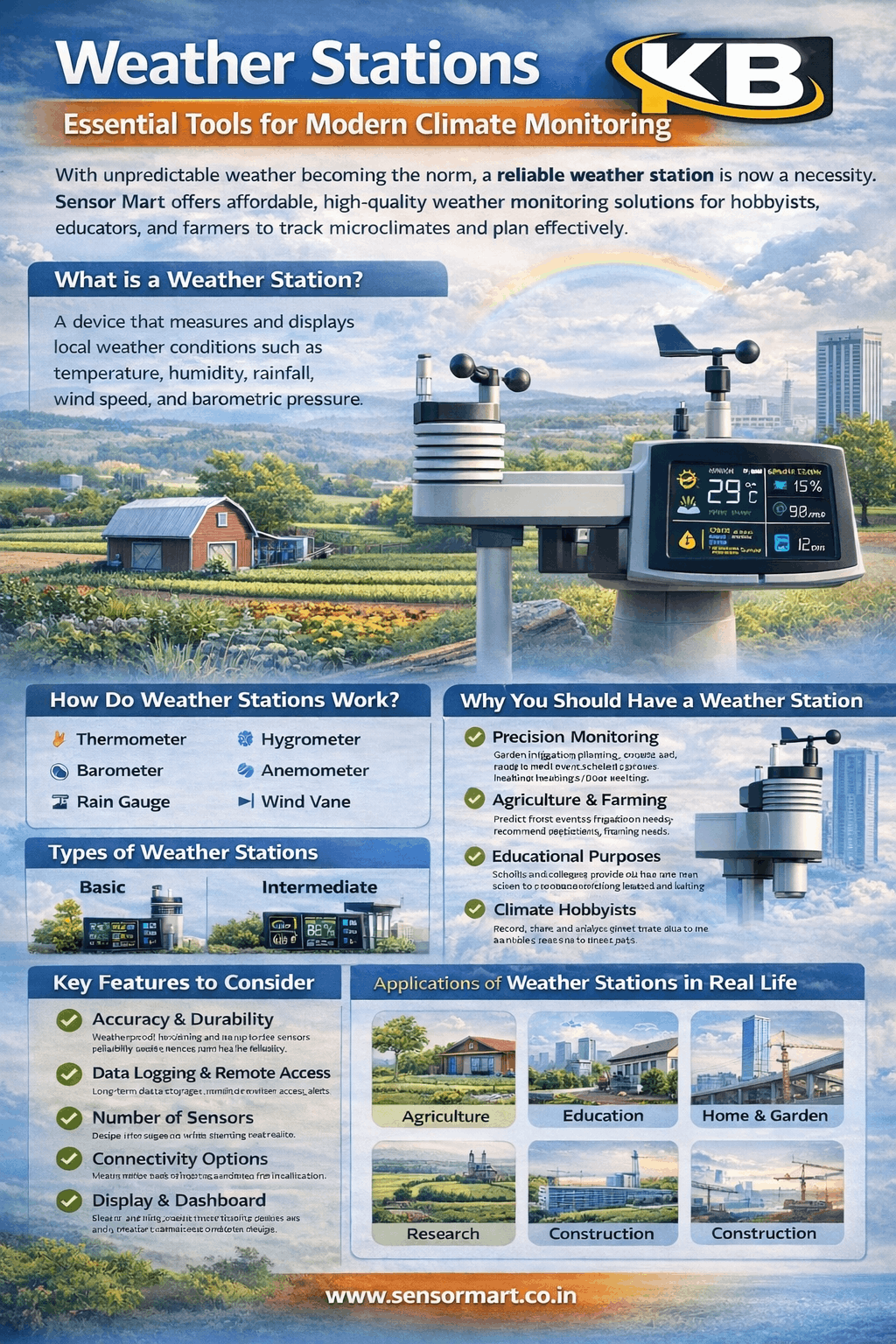

II.B. Environmental Telemetry and Monitoring

A significant operational segment involves the long-term support of sensitive environmental sensors. This is the domain of telemetry, where instruments track weather, soil chemistry, or solar irradiance. For these tasks, the tripod must offer substantial vertical extension to clear ground clutter or foliage, ensuring accurate, unobstructed readings. Specialized models reach considerable heights, with some industrial stands designed to provide an expansive aerial purview up to 304.8 centimeters (10 feet) or even 381 centimeters (12.5 feet). The inherent stability of these robust, fixed platforms is crucial to preventing vibrational artifacts from corrupting the delicate data stream transmitted by the sensors.

III. Engineering for Exigence: Materials and Load Dynamics

The structural integrity of a tripod stand begins with its constituent elements, which must be selected based on the specific mechanical stresses and environmental volatility anticipated in the workspace.

III.A. The Triad of Construction Materials

The modern industrial stand primarily relies on a triad of materials. Aluminum alloys are popular for achieving a superior strength-to-weight ratio, allowing for robust load-bearing capabilities while maintaining relative portability. Stainless steel is often chosen where superior antifouling and corrosion resistance are primary concerns, particularly in humid or chemically aggressive environments. While less common in modern in situ applications, specialized wood varieties (like beech or birch) are sometimes still used in highly refined metrology for their inherently superior vibration dampening characteristics and resistance to rapid thermal expansion.

III.B. Quantifying Stability: Torsional Rigidity and Safe Working Load

True measure of an industrial support’s quality lies in its quantified performance metrics. The Safe Working Load (SWL) is the non-negotiable capacity limit that dictates the maximum static weight the structure can bear. Equally vital is the concept of torsional rigidity, which measures the unit’s resistance to twisting forces. A tripod with low torsional rigidity will subtly shift its head plate under lateral pressure or wind loads, compromising the angular accuracy of the mounted device. The superior design minimizes deflection across all axes, a key trait separating a reliable platform from a potential liability.

IV. Features of Functional Superiority

Exemplary industrial tripod stands distinguish themselves through the integration of features that enhance field operations, moving them from passive supports to active, ergonomic tools.

IV.A. Articulation and Anchorage: Leg Systems and Geometry

Effective industrial deployment often occurs on uneven, unforgiving terrain, requiring precise leg manipulation. The most versatile industrial tripods feature leg adjustment angles that can be independently set at multiple, fixed intervals, such as 25°, 50°, and 75°. This capacity for individual leg articulation ensures that the instrument head can be perfectly leveled regardless of the underlying topography. The anchorage system—whether involving robust, spiked feet for soft ground or specialized rubber pads for concrete—must provide maximal coefficient of friction and steadfast adherence to the surface, preventing translational slippage.

IV.B. Operational Ergonomics: Cable Management and Rapid Deployment

In busy industrial sites, loose cables represent both a tripping hazard and a threat to sensor cables. Integrated cable management clips are a standard feature on high-quality sensor stands, ensuring that all power and data lines are neatly organized along the leg structure, reducing the risk of strain or accidental disconnection. Furthermore, the best tripods incorporate rapid-clamping or quick-action locking mechanisms to ensure high deployment efficiency. In time-sensitive scenarios, whether setting up a weather station ahead of a storm or securing a perimeter camera, the ability to transition from a folded transport state to full operational stability within seconds is an invaluable ergonomic advantage. The minimization of friction in the setup process ensures maximum field utility.

Buy Now: https://sensormart.co.in/big_tripod.php

https://sensormart.co.in/tripod.php

FAQs

What is the primary difference between a professional industrial tripod stand and a standard consumer-grade photography tripod?

The fundamental difference lies in their design mandate. Industrial tripods are built for structural exigence and persistent, high-load environments, prioritizing unimpeachable perpendicularity and safety over lightweight portability. They use heavy-duty materials like high-grade aluminum or stainless steel to resist dynamic loads, whereas consumer models focus on optical stabilization for lighter equipment and finite-duration use.

Why is “Torsional Rigidity” considered a key metric for industrial tripod quality?

Torsional rigidity measures a tripod’s resistance to twisting forces. For precision tasks like geomatic surveying or metrology, low rigidity would allow the head plate to subtly shift under pressure or wind, compromising the angular accuracy of the mounted device. High torsional rigidity ensures the instrument maintains its precise orientation, guaranteeing data fidelity.

For Environmental Telemetry and monitoring sensors, what specific features should I look for in an industrial tripod?

You should prioritize models that offer significant vertical extension (up to 381 cm/12.5 ft) to achieve an adequate aerial purview above ground clutter. Additionally, look for independent leg articulation (like 25°, 50°, and 75° angle settings) to level the instrument on uneven terrain, and integrated cable management clips to prevent vibrational artifacts and cable strain from corrupting the delicate data stream.

Q: Which construction materials are best suited for mitigating measurement error due to thermal expansion or vibration?

While aluminum alloys offer a great strength-to-weight ratio, specialized wood varieties (such as beech or birch) are often preferred in highly refined metrology. Wood exhibits superior natural vibration dampening characteristics and is less susceptible to rapid thermal expansion compared to metals, which minimizes horizontal drift and ensures absolute constancy in measurement.

Q: Why are advanced anchorage systems, like spiked feet or special rubber pads, so critical for industrial use?

The anchorage system is crucial for achieving anti-overturn prophylaxis and preventing translational slippage. Spiked feet ensure maximal grip and stability on soft or uneven outdoor terrain, while specialized rubber pads are necessary for providing a high coefficient of friction and steadfast adherence when deploying the stand on hard, polished, or concrete industrial floors.

Leave a Reply