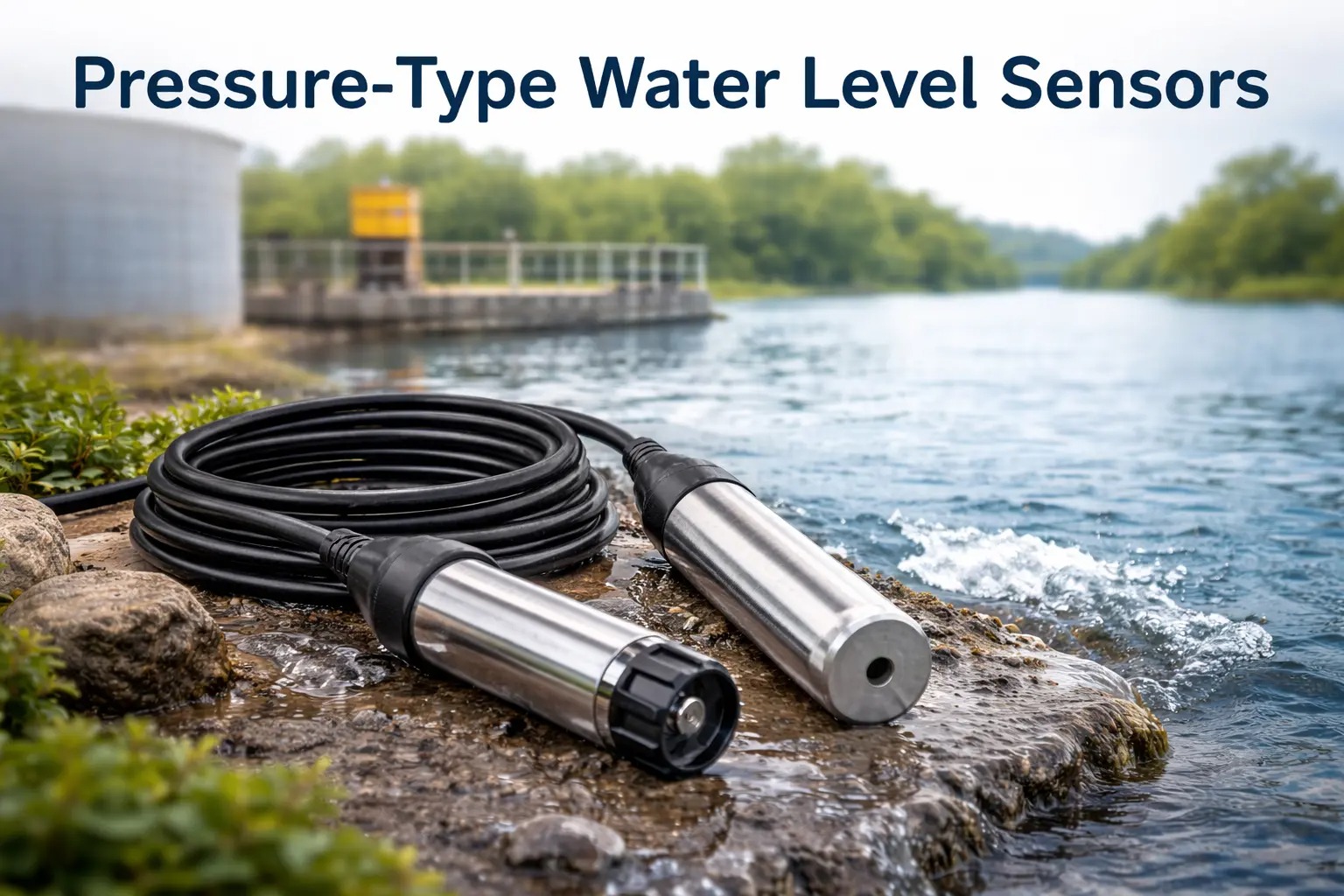

A Simple Guide to Pressure-Type Water Level Sensors in Practice

Water level measurement is a daily need in many industries, farms, and public systems. Tanks, wells, rivers, and reservoirs must be checked regularly to avoid loss, overflow, or damage. Modern monitoring systems rely on simple but reliable tools to do this work without confusion. Pressure-type water level sensors play a key role because they give stable readings and work well in real conditions. Their design is practical, their operation is easy to understand, and their results help people take the right action at the right time.

What Pressure-Type Water Level Sensors Are

Pressure-type water level sensors are devices that measure water level by sensing the pressure created by the water above them. When water depth increases, pressure increases. When the water level drops, the pressure reduces. The sensor reads this change and converts it into a clear water level value.

These sensors are placed directly inside the water. They are usually installed at the bottom of a tank, well, or channel. The weight of the water column presses on the sensor, and this pressure becomes the main measurement signal. This simple method makes them reliable for long-term use.

Due to their straightforward working principle, these sensors are trusted in numerous real-world applications. They do not require complex setups and can function effectively even in remote or harsh environments.

Key Components Inside the Sensor

Sensing Element and Housing

The sensing element is the heart of the sensor. It reacts directly to pressure changes. The housing protects this element from water damage, dirt, and external stress. Strong housing allows the sensor to work in deep or rough water conditions.

Signal Output System

After sensing pressure, the signal is sent through cables to a monitoring system. This output can be connected to data loggers, controllers, or alarm systems. The clear signal helps operators understand water levels easily.

Each component works together to provide accurate and stable readings. This simple structure is one reason why these sensors last long and need little maintenance.

Real-World Applications in Water Tanks

In water storage tanks, level monitoring is very important. Overfilling can cause leakage, while low levels can interrupt supply. Pressure-type water level sensors are often placed at the bottom of tanks to track changes throughout the day.

These sensors help manage water supply in buildings, factories, and housing projects. When connected to automated systems, they can trigger pumps to turn on or off at the right time. This reduces water waste and saves energy.

Their ability to work continuously makes them suitable for both small tanks and large industrial storage units. This makes daily operations smoother and more reliable.

Use in Wells and Boreholes

Wells and boreholes require careful monitoring to avoid overuse or pump damage. Water levels in these sources can change due to seasonal factors or heavy usage. Pressure-based sensors help track these changes without manual effort.

Installed deep inside the well, the sensor measures pressure from the water column above it. This data helps users understand groundwater behavior. It also supports safe pump operation by preventing dry running.

In rural and industrial areas, such monitoring helps manage water resources better and ensures long-term availability.

Role in Rivers and Open Channels

Monitoring water levels in rivers and canals is essential for flood control and irrigation planning. Pressure sensors are often placed at fixed points where water depth changes are important.

These sensors provide continuous data even during heavy rain or fast flow. Their design allows them to stay stable underwater without affecting the flow itself. This makes them useful for long-term environmental monitoring.

Authorities and planners use this data to issue warnings, manage gates, and plan water release schedules safely.

Benefits in Industrial Environments

Industries use large amounts of water for processing, cooling, and cleaning. Any mistake in water level control can cause loss or safety risks. Pressure-based sensors help maintain strict control.

They can work in harsh conditions, including high temperature or chemical exposure, when designed correctly. This makes them suitable for factories and plants where conditions are not always ideal.

Their reliable readings support automation and help reduce manual inspection needs. This improves safety and efficiency across industrial operations.

Accuracy and Reliability in Daily Use

Accuracy is one of the main reasons these sensors are trusted. Since pressure changes directly match water height, readings remain consistent. Proper calibration ensures correct results over long periods.

Reliability also comes from their simple design. Fewer moving parts mean fewer chances of failure. Once installed correctly, they can operate for years with minimal attention.

This combination of accuracy and stability makes them ideal for real-world use where constant monitoring is needed.

Installation and Maintenance Considerations

Installation is usually simple. The sensor is lowered to a fixed depth and secured properly. Correct positioning ensures accurate readings. It is important to avoid placing the sensor where debris can block it.

Maintenance needs are low. Periodic checks help ensure the sensor remains clean and properly connected. In most cases, routine inspection is enough to keep it working well.

Because maintenance is minimal, these sensors reduce long-term operational costs.

Why Sensormart Is a Trusted Choice

Choosing the right supplier is as important as choosing the right technology. Sensormart offers solutions designed for real Indian conditions, where water systems vary widely.

Products from Sensormart focus on durability, accuracy, and ease of use. Their range supports different applications, from simple tanks to complex monitoring systems.

Clear product information and dependable support help users get the best results from their installations. This makes monitoring tasks simpler and more effective over time.

FAQs

1. How do pressure-based water level sensors measure depth?

They measure pressure created by the water column above the sensor and convert it into a water level reading.

2. Are these sensors suitable for deep-water applications?

Yes, they are designed to work at different depths, depending on their pressure rating and installation method.

3. Do pressure sensors work in flowing water?

They can work in flowing water if installed correctly at stable points where pressure readings remain consistent.

4. How often do these sensors need maintenance?

Maintenance is minimal and usually involves occasional inspection and cleaning to ensure accurate readings.

5. Can these sensors be connected to automated systems?

Yes, they can be linked to controllers, alarms, and data loggers for automatic monitoring and control.

6. Why is brand quality important for water level sensors?

Good quality ensures accuracy, durability, and long service life, reducing errors and long-term costs.

Conclusion

Understanding how pressure-type water level sensors work helps users trust their data and use it wisely. Their simple principle, strong design, and real-world reliability make them a smart choice for many applications. From tanks and wells to rivers and industries, they support safe and efficient water management. When paired with reliable solutions from Sensormart, these sensors become a powerful tool for long-term monitoring. In daily operations where water control matters, dependable measurement always makes a real difference.

Leave a Reply